Metal casting riser design calculation Riser design example problems YouTube

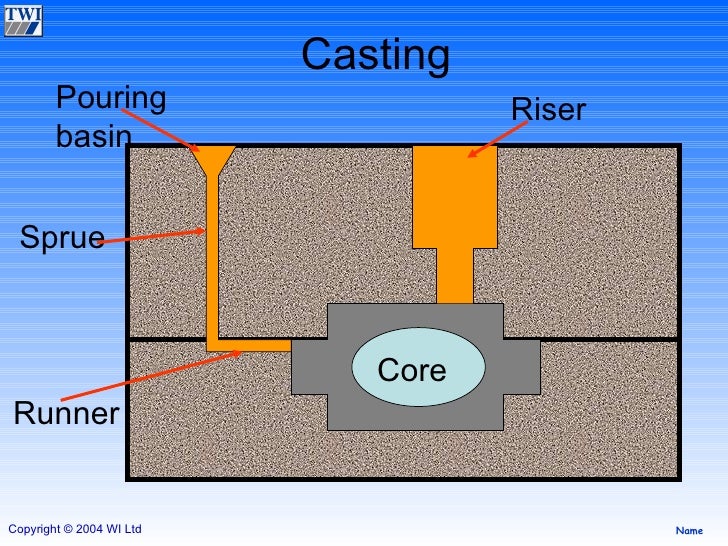

A riser, also known as a feeder, [1] is a reservoir built into a metal casting mold to prevent cavities due to shrinkage. Most metals are less dense as a liquid than as a solid so castings shrink upon cooling, which can leave a void at the last point to solidify.

Metals Free FullText Heating System for Riser Size Minimizing in Sand Casting Process and

This course guides participants through the basic functions of gating and risers to provide clean, sound, and functional castings. An introduction to fluid flow and solidification will serve to guide participants through key design concepts of the various functional elements of good gating and riser design. Emphasis will be placed on hands-on.

Sand Casting Molds Overview Of Casting Technology atelieryuwa.ciao.jp

A riser (or feed head) is an opening through the cope. Its main purpose is to feed the molten metal to the casting as it solidifies i.e., to compensate for the shrinkage. The risers also serve as a large vent for generated steam and gases and afford a place for collecting loose sand or slag.

Different Metal Casting Processes used in the Manufacture of Parts

A riser in the casting process is a passage in the casting mold which prevents casting shrinkage defects and is designed into the casting mold. Once the liquid metal has solidified, the riser is removed from the mold. A riser reduces the number of defects in the casting materials, hence improves the number of defect-free products of the process.

Winstead Multi Function Riser Slide Shower Rail Kit round

Functions of riser: Riser ensure the complete filling of the cavity so that the sound casting can be produced. Clearly riser functions can be divided into four categories. Used to compensate shrinkage (Liquid and solidification). Ensure complete filling of the cavity. Make the dense/compact casting.

Riser Design Metal Casting Production Process 1 YouTube

Contents show Riser Riser is a source of extra metal which flows from riser to mold cavity to compensate for shrinkage which takes place in the casting when it starts solidifying. Without a riser heavier parts of the casting will have shrinkage defects, either on the surface or internally.

Die Casting vs Sand Casting A Guide for Making the Right Choice

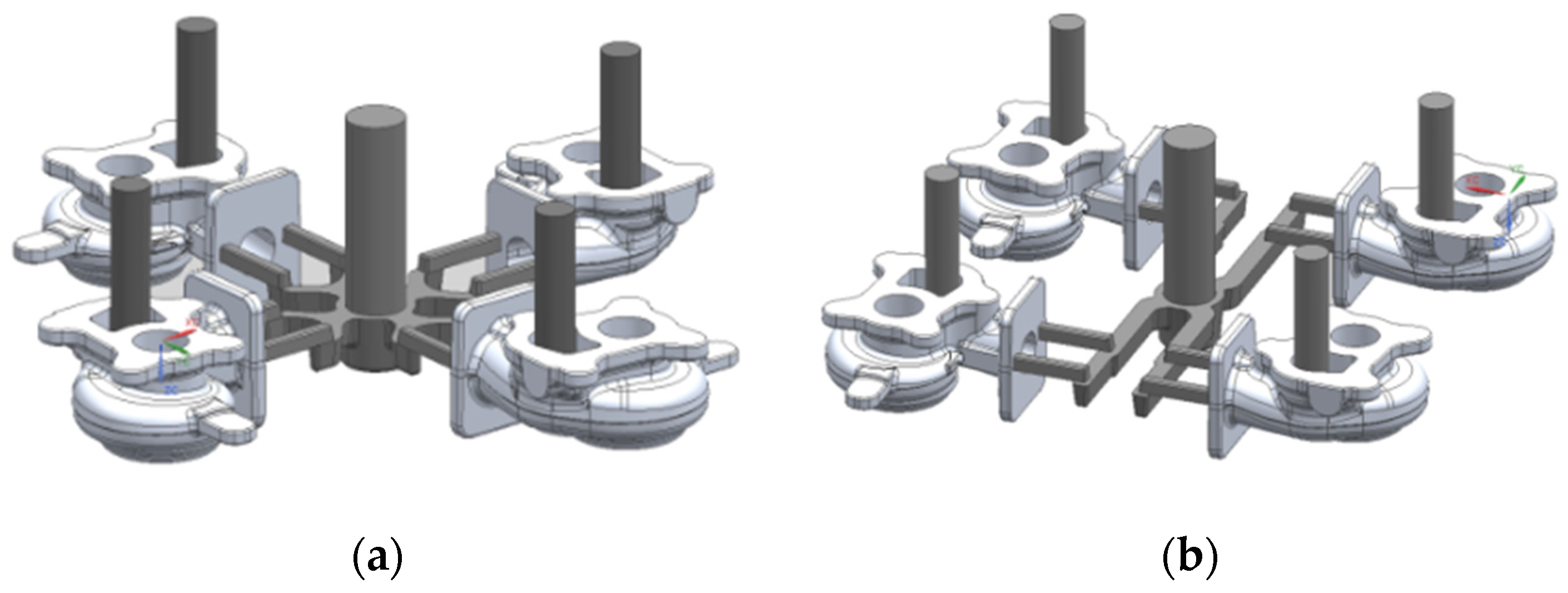

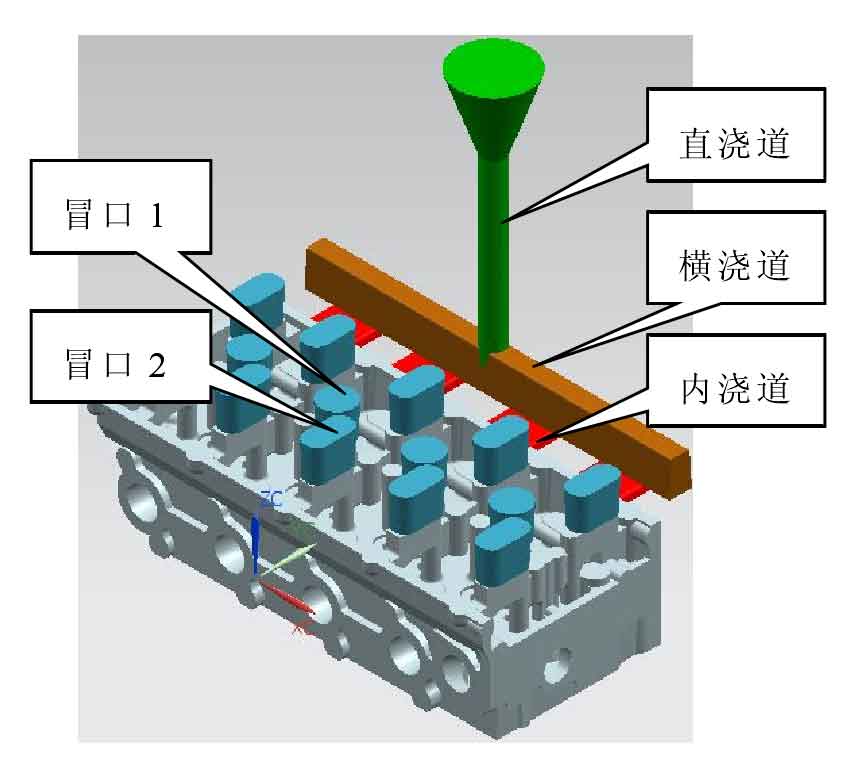

The process optimization process of gating system and riser system is given in detail by actual castings. The application results indicate that the integrated system can realize the process optimization of steel castings and provides new ideas and key technology for intelligent process design of steel castings.

Design of riser in sand casting ZHY Casting

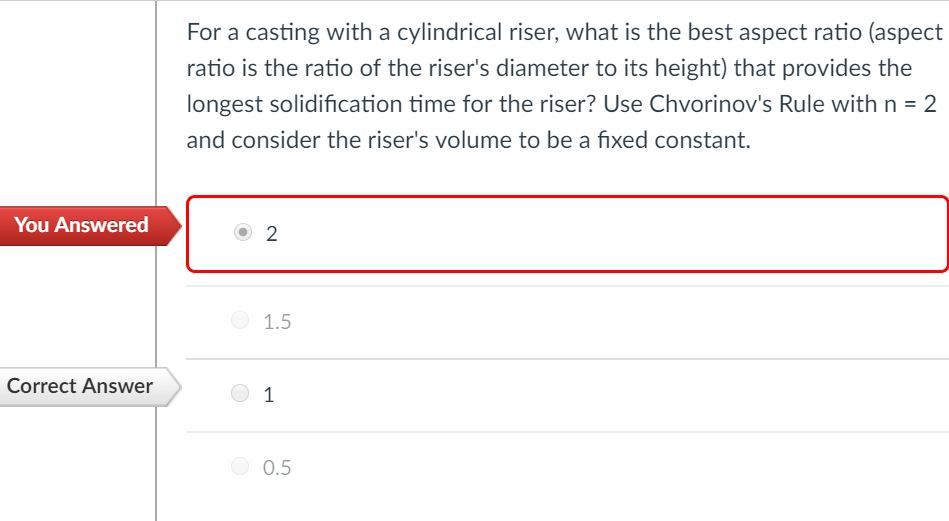

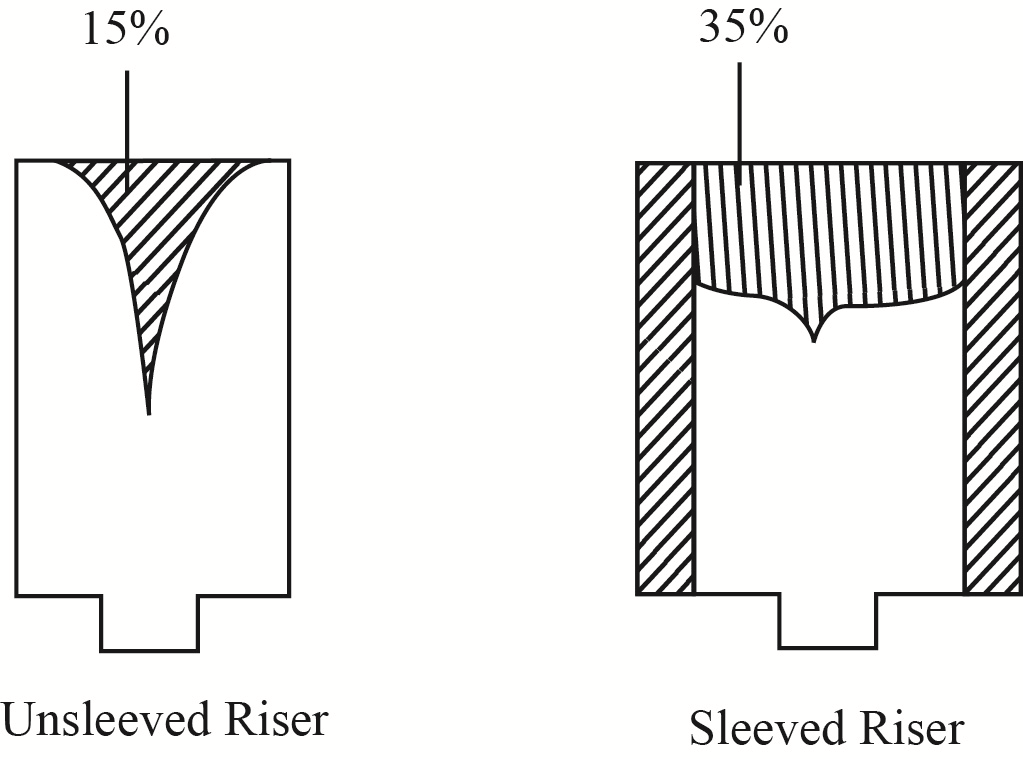

BASIC THEORY OF RISER DESIGN Riser design for shrinking alloys is based on a simple premise; as metal cools and solidifies, it shrinks, or contracts. Risers must be large enough to solidify after the casting, or casting section, being fed, and must have enough volume to provide enough 'feed metal' to offset casting shrinkage.

Solved For a casting with a cylindrical riser, what is the

Explanation : A riser, also known as a feeder, is a reservoir built into a metal casting mold to prevent cavities due to shrinkage. Most metals are less dense as a liquid than as a solid so castings shrink upon cooling, which can leave a void at the last point to solidify. What is difference between runner and riser?

Casting modulus

Risers and runners Published - 21st Jan 2016 In this blog, we take a look at the important role played by risers and runners in sand casting. Risers These are vertical channels that provide a continuous flow of molten metal to eliminate shrinkage as solidification occurs during the casting process.

Cloud Comfort Multi Function Riser Recliner Murrays.ie

Risering Iron Castings This module identifies the uniqueness of feeding graphitic cast iron alloys. The three ways that risers should be designed for cast iron are explained along with the factors that affect volume change. By the end of this module, you will be able to list unique riser considerations for iron castings. (0.1 CEU)

Ut P5 (Product Tech.)

Riser Design (Casting) Definition: Riser is defined as a reservoir for supplying molten metal to the casting cavity to compensate (additional molten metal) the liquid shrinkages taking place due to solidification. Shape of riser: It's shape is almost cylindrical since it takes more time to solidify than sphere and cube shape.

Solved Chapter 9 Problem 113P Solution The Science And Engineering Of Materials 7th Edition

open access • This paper deals with the interconnection between the manufacturing industries (casting) and the concept of optimization. • It aims to bring out the use of various software that helps the production industry design and analyse the overall casting process.

Chapter 10 Fundamentals of Metal Casting Copyright PrenticeHall

Different ways to calculate the geometry of the riser . Casting is an important industrial process for manufacturing near net-shaped products such as engine blocks, crankshafts, and turbine blades. Among various shape casting methods, sand casting is very common, and more than 80% of casting parts is produced by this method [5]..

Riser design of casting process for cast steel joint ZHY Casting

The primary function of riser as attached with the mould is to feed molten metal to accommodate shrinkage occurring during solidification of the casting.

Alumina Ceramic Parts Riser in casting Aluminium Adtech China

The gating system has several functions. They are: • Reduce turbulence. Low speed means low turbulence (less erosion, less splashing of metal). Air/ mold/core gases become entrained. • Reduce entrapped air/gases. This is caused by turbulence, also due to formation of low pressure areas within the gating system.